Safety Guidelines and Precautions

Always follow essential safety measures before operating the Porter Cable 150 PSI Compressor. Ensure proper ventilation‚ avoid overloading‚ and regularly inspect hoses and connections for damage or leaks.

1.1 Essential Safety Measures Before Operating the Porter Cable 150 PSI Compressor

Before operating the Porter Cable 150 PSI Compressor‚ ensure all safety precautions are met. Always wear protective gear‚ including safety glasses and gloves‚ to prevent injury from flying debris or accidental starts. Ensure the compressor is placed on a stable‚ level surface to avoid tipping. Check the oil levels and electrical connections before each use to prevent malfunctions. Never operate the compressor in enclosed spaces without proper ventilation‚ as this can lead to carbon monoxide buildup. Keep the area clear of flammable materials and ensure the compressor is turned off when not in use. Regularly inspect hoses and fittings for signs of wear or damage to prevent leaks or ruptures. Always follow the manufacturer’s guidelines for maximum pressure settings to avoid overloading the system. If unsure about any aspect of operation‚ consult the user manual or contact a professional. Proper safety practices ensure efficient and hazard-free operation.

Product Specifications and Technical Details

The Porter Cable 150 PSI Compressor features a robust design‚ delivering reliable performance for both industrial and residential applications‚ ensuring efficient air compression with minimal noise.

2.1 Overview of the Porter Cable 150 PSI Compressor’s Key Features

The Porter Cable 150 PSI Compressor offers a maximum pressure of 150 PSI‚ making it suitable for various applications. It features a durable construction‚ efficient cooling system‚ and a user-friendly interface. The compressor is designed to provide consistent performance‚ ensuring minimal downtime. Its compact design allows for easy installation and portability. Additionally‚ it comes equipped with safety features such as pressure relief valves and thermal overload protection. The compressor also includes a comprehensive user manual‚ detailing installation‚ operation‚ and maintenance guidelines for optimal functionality and longevity.

Installation and Setup Instructions

- Follow the user manual for proper installation and ventilation.

- Ensure the unit is placed on a stable‚ level surface.

- Connect hoses securely and test the system under no load.

3.1 Step-by-Step Guide to Properly Installing the Compressor

- Unload the compressor carefully and inspect for damage.

- Choose a well-ventilated‚ level surface for installation.

- Mount the compressor securely to prevent vibration.

- Connect the power supply according to the manual’s specifications.

- Install the air filter and ensure proper alignment.

- Connect hoses and test the system under no load condition.

- Verify all safety features are functional before operation.

Follow these steps to ensure safe and optimal compressor performance.

Maintenance and Troubleshooting Tips

Regularly check oil levels‚ inspect hoses for leaks‚ and clean the air filter to ensure optimal performance. Address any unusual noise or vibration promptly to prevent damage.

4.1 Common Issues and Solutions for the Porter Cable 150 PSI Compressor

Common issues include low oil levels‚ air leaks‚ and uneven pressure. Solutions involve checking and refilling oil‚ inspecting hoses for cracks‚ and adjusting the pressure regulator. Additionally‚ unusual noise may indicate worn belts or dirty filters‚ which should be replaced or cleaned promptly. Regular maintenance‚ such as draining moisture from the tank and lubricating moving parts‚ prevents breakdowns. Always refer to the manual for specific troubleshooting steps to ensure safe and effective operation of the compressor.

Accessories and Compatible Tools

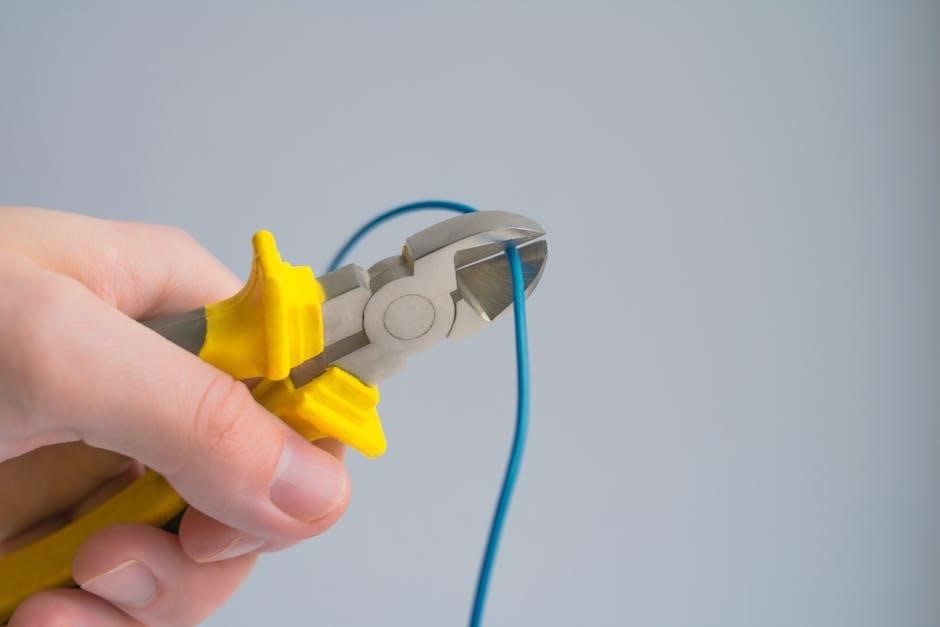

Recommended accessories include air hoses‚ spray guns‚ and nailers. Ensure compatibility with Porter Cable 150 PSI Compressor for optimal performance in various applications like painting and fastening.

5.1 Recommended Accessories for Optimal Performance

To enhance the functionality of the Porter Cable 150 PSI Compressor‚ consider investing in high-quality accessories. A durable air hose with proper threading ensures reliable connections and consistent airflow. Spray guns and nailers designed for high-pressure applications are ideal for various projects. Additionally‚ air filters and pressure gauges help maintain efficiency and accuracy. Quick-connect couplers simplify tool changes‚ while a moisture trap prevents water damage. For heavy-duty tasks‚ a coil or framing nailer is recommended. These accessories optimize performance and versatility‚ making the compressor suitable for both professional and DIY applications.

Understanding Pressure Settings and Operations

Ensure adjusting the Porter Cable Compressor’s 150 PSI setting requires careful monitoring of pressure gauges. Maintain optimal levels for efficiency and safety in various applications.

6.1 How to Adjust and Monitor the 150 PSI Setting Effectively

Start by turning off the compressor and allowing it to cool. Check the tank pressure gauge to ensure it matches the desired setting. Use the regulator knob to adjust the output pressure‚ monitoring the gauge closely. Always operate within the recommended 150 PSI range to avoid damage. Regularly inspect the pressure gauge for accuracy and ensure all connections are secure. Refer to the manual for specific calibration instructions if needed. Proper monitoring ensures safe and efficient operation of the Porter Cable 150 PSI Compressor.

Warranty and Customer Support Information

The Porter Cable 150 PSI Compressor is backed by a 1-year limited warranty. For support‚ contact their customer service team via phone or email for assistance with repairs or replacements.

7.1 Coverage and Assistance Options for the Porter Cable Compressor

The Porter Cable 150 PSI Compressor is covered by a 1-year limited warranty‚ protecting against defects in materials and workmanship. For assistance‚ customers can contact Porter Cable’s customer support team via phone‚ email‚ or through their official website. Additional resources‚ such as troubleshooting guides and repair manuals‚ are available online to help resolve common issues. Warranty claims require proof of purchase and may need pre-approval from Porter Cable. Registered users can also access extended support options‚ ensuring reliable assistance for maintenance and repairs.

User Reviews and Ratings

Users praise the Porter Cable 150 PSI Compressor for its durability and consistent performance. High ratings highlight its reliability and ease of use‚ making it a top choice for home and professional tasks. Many recommend it for its efficiency and value.

8.1 Feedback from Customers Using the Porter Cable 150 PSI Compressor

Customers praise the Porter Cable 150 PSI Compressor for its efficiency and durability. Many highlight its reliable performance and ease of use‚ making it suitable for both home and professional tasks. Users appreciate its portability and consistent air pressure delivery. Some mention its quiet operation compared to other compressors in its class. A few note that the setup process is straightforward‚ and the included accessories enhance its functionality. Overall‚ the compressor receives high ratings for its value for money and is often recommended for various applications.

Environmental and Storage Considerations

Store the Porter Cable 150 PSI Compressor in a dry‚ cool place‚ away from direct sunlight. Ensure proper disposal of fluids and recycle materials when possible.

9.1 Proper Storage and Environmental Recommendations

Store the Porter Cable 150 PSI Compressor in a dry‚ well-ventilated area away from direct sunlight and moisture. Avoid extreme temperatures and ensure the unit is clean before storage. Regularly drain excess water from the tank to prevent rust. Use protective covers to shield from dust and debris. Dispose of waste materials responsibly‚ adhering to local environmental regulations. Proper storage helps maintain efficiency and extends the compressor’s lifespan while minimizing environmental impact.

Compliance and Certification Details

The Porter Cable 150 PSI Compressor meets industry standards and certifications‚ ensuring safe and reliable operation. It complies with environmental regulations and safety requirements for air compressors.

10.1 Industry Certifications and Compliance Standards

The Porter Cable 150 PSI Compressor adheres to rigorous industry certifications and compliance standards. It meets UL (Underwriters Laboratories) and ETL (Intertek) certifications‚ ensuring safe and reliable operation. The compressor complies with environmental regulations‚ including energy efficiency standards‚ and is designed to minimize ecological impact. Built to withstand demanding conditions‚ it aligns with ISO standards for air compressor performance and durability. Regular audits and testing ensure compliance with safety and operational requirements‚ making it a trusted choice for industrial and residential use. These certifications guarantee the compressor’s reliability and adherence to global quality benchmarks.